MAR-TRAIN HEAVY HAULAGE LTD., ESTABLISHED IN NORTHERN IRELAND MORE THAN FORTY YEARS AGO, HAS JUST OPENED A NEW BASE IN BERGEN, NORWAY, WHERE THE COMPANY IS SPECIALISING IN THE TRANSPORT OF COMPONENTS FOR WIND FARMS. MANAGING DIRECTOR TIM MARTIN HAS BEEN EXPLAINING TO HEAVYTORQUE HOW HEAVY HAULAGE DIFFERS IN THE LAND OF THE MIDNIGHT SUN.

As three heavy duty Volvo tractors struggled to move an 85-tonne tower section up a steep icy track on a windswept Norwegian mountain way beyond the Arctic Circle, Tim Martin must have had second thoughts about his decision to expand into Scandinavia. But it wasn’t the first risk he’d taken. Back in 2014, Lisburn-based Mar-Train had opened a new operation in County Limerick, in the Republic of Ireland, and became the first heavy haulage company to have both a UK and Irish haulage licence. It was its experience with moving wind turbine components on both sides of the border and throughout the UK which led to it working on a wind farm project in the north of Norway and ultimately to the establishment of Mar-Train Heavy Haulage (Norway) AS at the end of last year.

FAMILY-RUN PJ DOWNS & SONS HAS ACCRUED OVER 40 YEARS’ EXPERIENCE TRANSPORTING, BOATS, MASTS, MACHINERY AND MANY OTHER CARGO TYPES. HEAVYTORQUE TALKS TO SECOND GENERATION, ALLAN DOWNS ABOUT THE FIRM AND ITS LATEST FLAGSHIP SCANIA RIGID CRANE TRUCK.

The old saying ‘time and tide wait for no man,’ is particularly apt in road transport, where often as not you’re only as good as your last job. Timed deliveries are commonplace in our industry, but additionally, boat transporter PJ Downs & Sons also requires a good working knowledge of tides in and around the many harbours or marinas it’s worked in since 1979. The firm’s signature service has seen it transport virtually every type of vessel over the years, from houseboats, motor cruisers and racing yachts, right through to catamarans, royal barges and lifeboats. In 2012, the company also shifted all the masts and rigging from the famous Cutty Sark in Greenwich to Maldon for an off-site restoration, then returned them to the landmark vessel. Seven years later PJ Downs & Sons returned to the world’s only surviving extreme clipper to remove the figurehead, anchor and capstans. These key artefacts were then refurbished and brought back to Cutty Sark a few months later. The company always uses its own drivers to ensure that boats, whether racing, leisure or working, are treated with the utmost care throughout their respective journeys.

Issue Twenty Six: with 180 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

WHEN VOLVO INTRODUCED ITS NEW VERSION OF THE I-SHIFT AUTOMATED TRANSMISSION IN MARCH 2016, WITH THE OPTION ON EITHER ONE OR TWO VERY LOW RATIO CRAWLER GEARS, THE HEAVY HAULAGE WORLD SAT UP AND TOOK NOTICE. HEAVYTORQUE CATCHES UP WITH AE YATES, ONE OF THE FIRST OPERATORS TO USE THE VEHICLE WITH THE NEW TRANSMISSION.

Bolton-based AE Yates Group, is a civil engineering, piling, soil stabilisation, horizontal directional drilling and specialist construction services company, which operates its own heavy haulage division. It had recently replaced its existing FH16/600 6×4 tractor unit, with a new FH16/750 8×4 Tridem tractor equipped with both the I-Shift crawler transmission and fully air-suspended rear bogie. The truck had already impressed both the operator and its regular driver with its early performance, so we were keen to see how it had fared over the intervening four years or so.

Most heavy transport professionals only really make a judgement about any new piece of technology until it has got a few years hard work behind it, following the mantra that almost everything is good when it’s new – what’s it like when it’s not! Previously Volvo had experienced mixed results with the earlier 12-speed I-shift in heavy applications.

OVER THE YEARS, LENGTH AND OPERATIONAL REQUIREMENTS HAVE CONSIGNED BONNETED TRUCKS TO THE PAST IN MOST AREAS APART FROM NORTH AMERICA. HOWEVER, THERE ARE STILL SOME ENTHUSIASTS WHO ARE ARE PREPARED TO PAY FOR WHAT THEY REALLY WANT. HEAVYTORQUE EXPLAINS HOW SPECIALIST CONVERTERS ARE ADAPTING EXISTING FORWARD CONTROL VEHICLES TO MEET THEIR CUSTOMER’S REQUIREMENTS.

At one time bonneted tractor units were a regular feature of heavy haulage operations. British manufacturers such as Scammell built normal control designs covering the entire weight range, from a 25-tons Highwayman to a 240-tons Contractor. They created a huge impression upon all who saw them, but gradually the more compact forward control designs won out for all but the most specialist of heavyweight applications.

Bonneted trucks still dominate the North American market and are popular for road-train and heavy haulage operations in Australia, but in most other markets they are consigned to history as far as new trucks sales are concerned.

Issue Twenty Six: with 180 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

BASED IN THE EAST MIDLANDS THE COLLINS EARTHWORKS GROUP, WHICH OFFERS A WIDE RANGE OF SERVICES, HAS AN EXTENSIVE FLEET OF OVER 50 VEHICLES IN ITS TRANSPORT DIVISION AND ACHIEVES OVER 3,000 MOVEMENTS OF HEAVY PLANT EQUIPMENT EACH YEAR AND, AS HEAVYTORQUE FINDS OUT, HAS A LOYALTY TO VOLVOS.

Collins Earthworks Group is well known for its strong allegiance to Volvo products. Its transport division, which includes tippers, heavy tractor units for the low-loaders and even the chassis for its road sweepers, all come from the Swedish manufacturer. But it doesn’t end there, the construction equipment fleet is dominated by Volvo – excavators, dump trucks and graders. If Volvo makes it, Collins almost certainly operates it. The transport division is responsible for shifting all of this equipment, along with other non-Volvo equipment, which includes bulldozers, tracked crushers and screening plant, soil stabilisation machines and a host of other lighter machines and assorted equipment.

The company aims to be as self-sufficient as possible, using its own equipment on major projects and only cross-hiring machinery from others if really necessary. The same applies with the transport operation.

FROM OLD BANGERS TO BOMB-PROOF WINDOWS, THERE’S NOT MUCH HERBIE’S HAULAGE HASN’T MOVED SINCE THE BUSINESS WAS ESTABLISHED A SHADE LESS THAN TWO DECADES AGO. HEAVYTORQUE CAUGHT UP WITH OWNER DARREN ‘HERBIE’ HERBERT TO LEARN A LITTLE MORE.

If you want something large shifting and you’re based in the Northamptonshire area, then there’s a pretty good chance that you’ll be pointed in the direction of Herbie’s Haulage. Established in 2002, the low-loader and crane vehicle specialists has made quite a name over the past 19 years. Thanks in part to the business’s larger-than-life owner. Darren Herbert, aka ‘Herbie’, has built the company from scratch and now runs a fleet of eight Volvo trucks, transporting a wide range of heavy-duty machinery all around the UK.

“I’ll move everything and anything. As long as it fits on the back of the lorry, then we’ll shift it,” he says. “In this day and age, you’ve got to be versatile. There are certain jobs we do more of, of course, but over the years we have transported most things you could imagine.”

Issue Twenty Six: with 180 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

MANY HEAVYTORQUE READERS COLLECT MODELS OF THEIR FAVOURITE TRUCKS, BUT DAVE WEEDON COLLECTS THE REAL THING. HE NOW OWNS SCORES OF CLASSIC HEAVY HAULAGE TRUCKS AND TRAILERS, AS WELL AS FIRE ENGINES, EXCAVATORS AND OTHER PLANT. HEAVYTORQUE HAS BEEN TO MEET HIM.

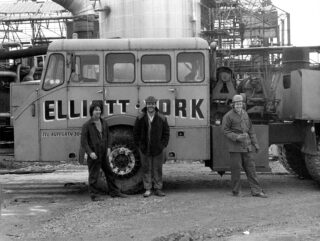

Dave Weedon has been passionate about big trucks since he was a small boy growing up in York. His best mate was Martin King, and Martin’s Dad, Lol King, was a driver with the legendary heavy haulage company, Elliott of York (see article on page 000). “We used to love being taken up to Elliott’s yard to look around,” Weedon tells me. “I remember Lol lifting us up into the new cab of their Pacific. It was fabulous. Lol used to drive a Scammell Highwayman, then a Foden S20, and sometimes he’d take us out with him. We used to take turns to sit on the bonnet, because there was only one seat. I loved it. When I got a bit older, me and my mate used to cycle up to Northallerton to look at the vehicles and trailers in Sunters’ yard, or go across to Pickfords in Leeds.”

By his own admission, Weedon wasn’t the most academic student, but he was good with his hands. He was always top of the class in woodwork, metalwork and art. He left school at 16 and joined Derwent Coachworks as a coachbuilder.

DESPITE THE CHALLENGES OF A GLOBAL PANDEMIC, TOTALKARE COMPLETED A MOVE TO NEW PREMISES DURING 2020, IN ADDITION TO SUPPLYING RECORD NUMBERS OF ITS NEW MOBILE BRAKE TESTER UNITS. HEAVYTORQUE TALKS TO CEO DAVID HALL ABOUT A BUSINESS THAT SHOWS NO SIGNS OF SLOWING.

There was no shortage of moving stories during 2020, a year in which the global COVID-19 pandemic changed everything we thought we knew about business. Despite this background of uncertainty and restrictions, West Midlands-based Totalkare still managed to relocate to a new, purpose-built premises in Kingswinford. This marked a major milestone for the firm, established in 1953 as Walter Somers Material Handling, which had been based in Halesowen.

Totalkare chief executive officer David Hall and his staff team had been planning the move since early 2019. “I’m a relative newcomer here with three years’ service,” says Hall. “However, it’s obvious that Totalkare is built on people. We’re not short of loyal, long-serving team members and these qualities are the reason our business has grown. Our company has a family-run feel with a professional structure and I value the staff experience considerably.”

Issue Twenty Six: with 180 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

ELLIOTTS OF YORK WAS A TRADITIONAL HEAVY HAULAGE COMPANY THAT DEVELOPED A REPUTATION FOR BEING ABLE TO MOVE PRETTY WELL ANYTHING UNTIL THE UNTIMELY DEATH OF ITS FOUNDER, EDWIN ELLIOTT, IN 1975. EDWIN’S SONS, EDWIN JUNIOR AND PETER, HAVE BEEN SPEAKING TO HEAVYTORQUE ABOUT THEIR FATHER’S REFUSAL TO BE BEATEN BY A LOAD.

Young Edwin Elliott was having a difficult day. It was the 1940s, Britain was at war, and he was trying to make a living with one of his first low-loaders, an old chain-drive Scammell with solid tyres. The Watford-based manufacturer had a reputation for building powerful vehicles that could move pretty well anything, but they weren’t too keen on stopping. And the brakes on Edwin’s Scammmell were particularly poor. He’d devised his own modification, involving a piece of rope tied to the foot pedal, which meant he was able to pump the brakes faster.

On this particular day, Edwin was moving a machine from York to Hull, but dropping down the hill into Bishop Burton the vehicle got away from him, and no amount of pumping the pedal could slow it down. In those wartime days there was little other traffic on the road, but to Edwin’s dismay, a solitary car came round the corner towards his rapidly accelerating low-loader.

Issue Twenty Six: with 180 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.